Manufacturing for the future of american aerospace

Aerospace Precision Machining

Digitrace tackles the most challenging and complex aerospace precision manufacturing. From ultra-thin walls to large structural components to extra-large machining parts to support your volume production, Digitrace is always ready to serve.

We help aerospace customers lift off and travel farther and perform better than ever before.

Partnership With ULA

In 2017, Digitracepartnered with ULA, one of the largest rocket manufacturers in the world, to develop a new machining process to reduce weight within the Vulcan Centaur V rocket. In order to accomplish this, Digitrace must hold tolerances of +/- .0001″ over surfaces that can exceed 160″ in length. This new machining process replaced a toxic and unpredictable chemical material removal technique that was previously being used.

Partnership With FAMAERO

FAMAERO has the world’s largest additive production metal 3D printer. After FAMAERO prints these large parts, Digitrace finishes off the project through subtractive manufacturing methods. We cut to the CAD data of their rough 3D printed part to make sure that it meets all aerospace tolerance requirements. Together, Digitrace and FAMERO are supporting the next era of space exploration.

customized tooling for aerospace industry

- Vacuum fixtures

- Checking fixtures

- Holding fixtures

- Bonding fixtures

- Models

- Forming tools

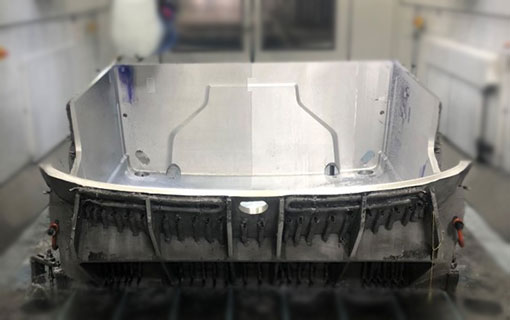

Bonding Fixture

Aerospace Tooling

Aerospace Tooling

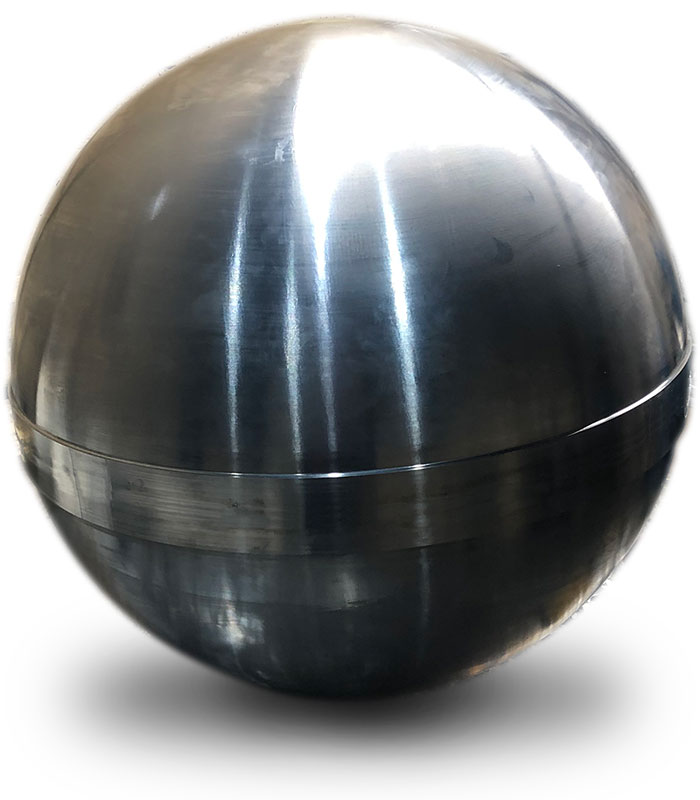

prototype parts

We provide prototype parts to help prove production feasibility. These parts can be made from different materials including ferrous and non-ferrous, plastics, and exotic materials.

Pictured here is a prototype titanium sphere produced by Digitrace for NASA. It was made in two pieces and welded together. The sphere, 32 inches in diameter, is 0.060 inches thick after completing the machining process.

production of large and small parts

- Sheet metal surface machining and trimming

- Titanium, Inconel, stainless, aluminum, ferrous & non-ferrous, plastics, carbon fiber, and many other materials

- Sheet metal bending and fabrication

- Aluminum extrusions in medium and low volumes