When failure is not an option

Defense precision machining

The Digitrace team combines advanced engineering, tireless customer collaboration, and best-in-field engineers and machinists to produce premium parts for multiple military applications. In air, on land and in water, Digitrace delivers extreme precision parts for when lives and enormous investments are on the line.

From programmers to machinists to account service staff and factory operations, our team is 100% focused on customer success.

Always DoD Ready

Digitrace is a firm believer in everything the United States of America stands for, and we will do everything in our power to support our warfighters. Our certifications prove that we have what it takes to machine high quality parts within the defense industry. Our large machining capabilities give us the ability to help in many ways, from the machining of large tanks to large weapon components to or large ship parts.

We’re committed to American values and we do everything in our power to supply the needs of the defense industry to support our U.S. military.

Please visit our capabilities page to see if Digitrace is a fit for your next project.

USS Gerald R Ford

As a tier 3 supplier for the building of the USS Gerald R Ford, Digitrace had the opportunity to machine components for the on deck elevator shafts as well as the bow of the ship. We could accommodate this project due to the large size of our machines. The elevators we machined were not like ordinary elevators that you ride in to get to your hotel room. These elevators need to carry our military’s fighter jets up from below deck. The large bulbous bow is required on ships in order to break the water in front of the ship. This lessens drag, which can increase speed and efficiency and reduce fuel usage, making it a critical part of the ship.

U.S. Navy

U.S. Navy valve made from titanium, machined by Digitrace, 3D printed by Famaero.

U.S. Army

Raw 3D printed sample by Famaero.

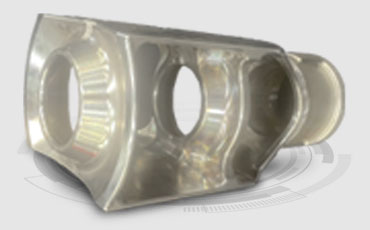

U.S. Army

U.S. Army engine intake cover made from inconel, machined by Digitrace, 3D printed by Famaero.

U.S. Army

U.S. Army muzzle brake machined by Digitrace, 3D printed by Famaero.